Bluetech Winners 2015

Bluetech Winners 2015

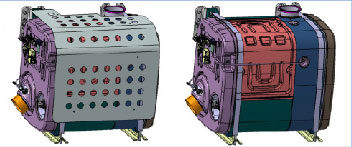

Category: Diesel Engine Pollution Control Technology

Applicant: Wuxi Weifu Lida Catalytic Converter Co., Ltd.

Description:

◎ Noble metal catalyst coating in DOC triggers oxidation reactions to oxidize HC, CO and a portion of particulate matters. The CDPF captures PM, where the PM is then burned by 1.) passive regeneration with the noble metal catalyst to help reduce temperature to 400℃, and 2.) active regeneration with diesel fuel injection to help reach higher temperature. The treated exhaust can satisfy the CN 5 emission standards.

◎ Installing the DPF fuel injection device will cause minimal changes to the engine, and the system can operate independently. Comprehensive and standardized calibration systems ensure DPF regeneration is quick, accurate, effective, and controlled so that the system can be re-used.

◎ The structure of the system is engineered so that the fogging coefficient UI≥0.95, raising the utilization rate of the catalyst and improving the system's ability to manage heat efficiency and reliability.

Environmental Effect:

Pollutant removal efficiency: CO>80%,PM>90%,PN>90%,HC>80%,NOx>90%.

Financial Impact:

System costs are varied and are based on different exhaust treatment requirements.

Application status:

This technology is in prototype stages, and the DPF system has not been commercialized yet.

Bluetech finalists 2015

Bluetech finalists 2015

The committee will use CAAC’s “Clean Air Technology Assessment Methodology” to assess the nominated technologies. The assessment will examine achieved performance and testing results to look for breakthrough potential in terms of environmental impact, technical performance and financial viability:

Environmental Impact: Pollution control efficiency and effectiveness, etc.

Technical Performance: Userfriendly design,operation performance and service life,etc.

Financial Viability: Initial installation cost, life cycle operation and maintenance costs,etc.

Clean Air Alliance of China. All rights reserved

京ICP備13044864號(hào)

Scan QR Code to view our Wechat